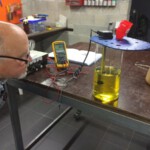

As usual when we don’t design a custom PCB we use a breadboard and pot it in epoxy to be resistant for vibrations, humidity, dirt, ….

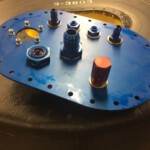

Because we had some additional potting tasks, we sealed also some isolation “boxes”. We use this to have a galvanic isolation between 12V and our logic signals.

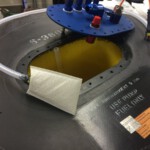

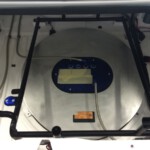

Now wait for 24 hours and …. ready to install.