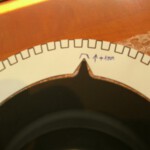

They are still very limited in number, but the main power lies in them.

Because the battery is at the very back and the BMW heart has a very significant dose of compression, we can miss any kind of voltage drop over the cable like the plague.

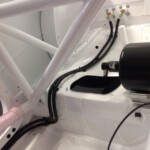

Hence the overgrown 50mm2 cables that we have safely steered through the back wall and bulkhead in our own way.

In order for the “big” cables not to be secured, we have paid some attention to this. Armed with a bar OF POM and a copper threaded rod, Luc has made custom made penetrations. Safety first !!

Now we only have to find suitable rubber covers to insulate the nuts.