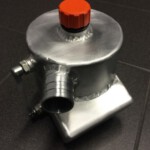

Because we always think too much about everything also the container to catch the oil damps has significantly changed. Version 1 was just something we bought, a nice red anodized container. But unfortunately these standard parts do not have

large vents to breath. Changing this means welding and then it’s hard to have it pass the aesthetic tests.

large vents to breath. Changing this means welding and then it’s hard to have it pass the aesthetic tests.